Quick Summary:

●The aisle width in VNA warehouse racking is approximately 1.6–2m, which results in increased storage capacity of up to 70%.

● VNA provides a better storage density and accessibility without compromising safety, which makes it an ideal solution for high-density operations.

● This is ideal for industries with high SKU volumes, such as FMCG, and in places like Dubai, where warehouse rent is high.

● Using VNA requires specialised equipment (turret trucks, stacker cranes), flat floors, staff training, and regular maintenance.

●A checklist to help you decide if VNA racking is right for your business.

With growing costs of storage facilities across the globe, maximising warehouse space has become essential for businesses. But logistics and supply chain managers struggle to optimise warehouse space.

A slight increase in inventory volume often becomes difficult to manage. So, what's the solution? The answer is VNA warehouse racking. This smart racking system transforms conventional warehouses into highly efficient storage solutions.

But what exactly is VNA racking and how does it help to maximise warehouse space? In this blog, we explore how VNA warehouse racking can improve storage efficiency, reduce costs, and integrate with automation to streamline your warehouse operations.

Table of Contents |

● What Exactly is VNA Warehouse Racking? ● What Are the Key Benefits of VNA Warehouse Racking? ● What Are the Ideal Applications for VNA Warehouse Racking? ● Comparing VNA Racking vs. Other Racking Systems ● Checklists to Decide if VNA Racking is Right for You ● Final Thought ● Frequently Asked Questions |

What is VNA Warehouse Racking?

Before explaining VNA warehouse racking, let's understand what racking is in a warehouse. It is a storage system to organise pallets and maximise warehouse space. VNA is one such specialised racking system.

VNA (Very Narrow Aisle) warehouse racking is a high-density warehouse layout design to maximise warehouse space by narrowing the aisles between pallet racks. Unlike conventional pallet racking systems, where aisle widths range from 3 to 4 meters, VNA racking reduces aisle dimensions between 1.5 and 2 meters. This helps you to store more pallets without expanding their footprint.

VNA racking requires specialised equipment, such as turret trucks or articulating forklift trucks, for manoeuvring quickly and efficiently in very tight aisle spaces.

Suggested Read: Pallet Racking vs Floor Stacking – Which One Should You Choose?

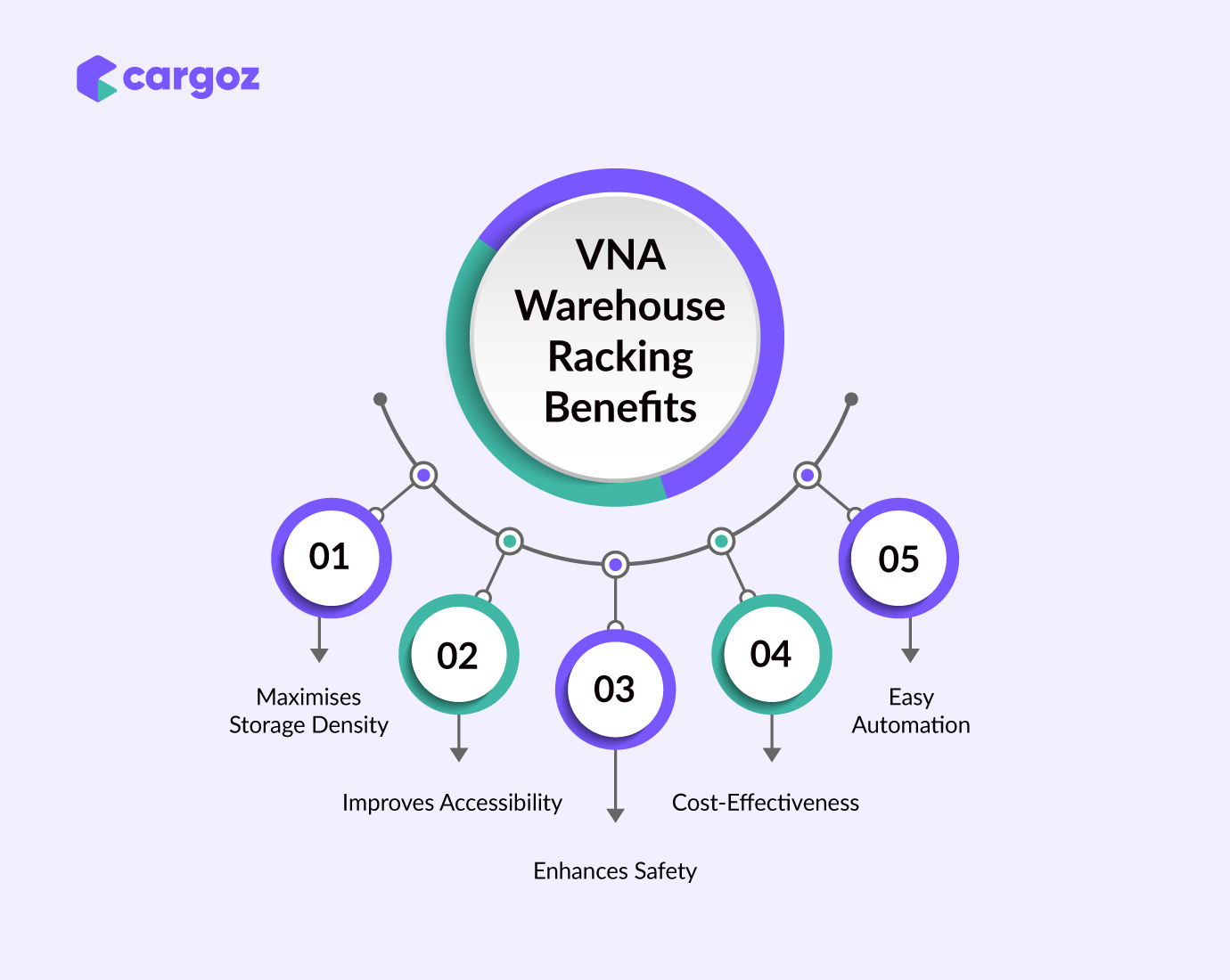

What Are the Key Benefits of VNA Warehouse Racking?

VNA warehouse is an ideal solution for businesses that need to maximise storage capacity without compromising accessibility. According to Europack, the VNA racking system optimises capacity by up to 70% while ensuring 100% pallet access. But this is not the only advantage of very narrow aisle warehouse racking systems. Here are the key benefits.

1. Maximises Storage Density

VNA storage racking reduces aisle space significantly, allowing businesses to maximise the warehouse space. This means that more pallets can be stored in the same footprint, which is very useful for high-density storage operations.

2. Improves Accessibility

Another important benefit of VNA systems is that they offer 100% pallet accessibility, even in high-density storage environments when used with specialised forklifts or turret trucks. This ensures that every pallet is easily accessible, thus accelerating warehouse operations and improving inventory management.

3. Enhances Safety

With guided systems for trucks, such as rails or wire guidance in VNA racking systems, the chances of collisions and product damage are minimised. This makes VNA warehouse racking a safer alternative to traditional wide-aisle setups.

4. Cost-Effectiveness

VNA Warehouse racking also allows you to store more goods in the same square footage. This allows businesses to avoid the need for warehouse expansion, which involves significant cost. By adopting a very narrow aisle racking system, your business can reduce the costs of real estate while ensuring long-term ROI. Moreover, combining VNA racking with on-demand warehousing solutions helps you to rent only the space you need.

5. Easy Automation

VNA warehouse racking can be integrated with automated systems to enhance efficiency. Automated storage and retrieval systems (AS/RS) trilateral stacker cranes can handle storage and retrieval tasks efficiently, ensuring a higher flow of pallets in the warehouse. Such automations reduce manual labour, minimise errors, and allow your team to focus on more complex tasks that require human intervention.

What Are the Ideal Applications for VNA Warehouse Racking?

VNA warehouse racking is preferred for businesses that deal with large volumes of goods. Here are the key applications of very narrow aisle warehouse racking systems.

1. Industries with High SKU Volumes

Retail, e-commerce, and pharmaceutical warehouses often manage thousands of unique products. VNA racking ensures each SKU is easily accessible while utilising vertical space effectively.

2. Warehouses in Costly Areas

In cities like Dubai, where the cost of a warehouse is significantly higher, you must make the most of available warehouse space. VNA racking systems enable businesses to store more pallets, thereby maximizing space utilisation.

3. Businesses with Fast-moving Goods

VNA racking provides both high-density storage and rapid retrieval for companies handling quick-turnover inventory, such as FMCG and e-commerce. It supports smooth operations and timely order fulfilment.

Comparing VNA Racking vs. Other Racking Systems

The table below provides a quick comparison of VNA racking system against selective pallet racking and drive-in racking to show where it stands out.

Feature | VNA Racking | Selective Pallet Racking | Drive-In Racking |

Aisle Width | 1.5–2.0 m (very narrow) | 2.5–4 m (wide aisles) | 2.5–4 m (shared lanes) |

Storage Density | High (better cubic utilisation) | Low–Medium | Very High |

Pallet Accessibility | 100% selectivity | 100% selectivity | Limited (LIFO system) |

Special Equipment Needed | Yes (turret trucks/stacker cranes) | No (standard forklifts) | No (standard forklifts) |

Safety | High (guided trucks reduce collisions) | Medium | Low (higher collision risk) |

Best Suited For | High SKU volumes in urban warehouses | General-purpose, low SKU counts | Homogeneous goods, bulk storage |

Checklists to Decide if VNA Racking is Right for You

Before investing in VNA warehouse racking, businesses should assess their operational priorities and constraints. Use the following checklist to evaluate if this system aligns with your needs:

- Do you have limited warehouse space and need to maximise space capacity?

- Is your facility located in a high-rent area where space optimisation reduces overhead costs?

- Do you manage a large number of SKUs that require both high density and 100% selectivity?

- Can you invest in specialised equipment such as turret trucks or trilateral stacker cranes?

- Is your warehouse floor sufficiently flat and even to support VNA equipment safely?

- Are you prepared to provide operator training and regular MHE maintenance?

If the answer is“yes” for most of these questions, VNA warehouse racking is likely to be an ideal fit for your storage strategy.

Final Takeaway

VNA warehouse racking system is a proven solution to optimise warehouse space utilisation and improve warehouse efficiency. Businesses seeking high-density storage with seamless access and enhanced safety must adopt this approach, especially in cities like Dubai, where warehouse costs are consistently rising. By leveraging these systems, supply chain managers can increase their storage capacity without compromising speed.

However, choosing the right warehouse is also critical to support VNA racking systems. Cargoz is a warehouse marketplace that helps businesses find verified warehouses in multiple locations in Dubai and across the UAE. Our experts can analyse your storage requirements and recommend the best solution. Contact us to find a warehouse in the UAE that supports VNA racking.

Frequently Asked Questions

1. What is VNA warehouse racking and how does it work?

VNA warehouse racking is a high-density storage system that reduces aisle widths. It allows more pallets to be stored while ensuring 100% accessibility using specialised forklifts or turret trucks.

2. What are the main advantages of VNA warehouse racking over traditional racking systems?

VNA warehouse racking maximises storage density, improves pallet accessibility, enhances safety, and reduces the need for expanding warehouse space.

3. Which types of warehouses are best suited for VNA racking?

Warehouses with high SKU volumes, limited space, fast-moving goods, and storage facilities in high-rent areas should use VNA racking systems.

4. What equipment is needed for operating VNA racking systems?

To use VNA racking systems, you will need specialised material handling equipment such as turret trucks, trilateral stacker cranes, and forklifts to manoeuvre efficiently in narrow aisles.

5. Can Cargoz help businesses find warehouses suitable for VNA racking in the UAE?

Yes, Cargoz is a warehouse marketplace that allows businesses to explore verified warehouses in the UAE that can accommodate VNA racking systems. You can contact us for your storage needs, and we will recommend the best option based on that.