Quick Go-through:

●Poor warehouse operations cost businesses over $1.5 trillion globally each year, highlighting the urgent need for performance evaluation.

●Understand key categories of warehouse performance metrics: inventory, order fulfilment, space utilisation, labour productivity, and compliance.

● Get formulas and examples to help you track and improve warehouse KPIs effectively.

●Discover the benefits of warehouse performance evaluation including reduced costs to faster delivery.

●See how Cargoz helps businesses rent high-performing warehouses with the right metrics in place.

- Poor warehouse performance can silently erode profit margins. Issues like delayed shipments, inaccurate inventory, and operational inefficiencies can result in lost revenue, customer churn, and rising overheads.

- According to a Tetrisize report, the global warehousing industry loses an estimated $1.5 trillion annually due to inefficiencies in inventory management, fulfillment errors, and underutilization of real estate.

- That's why warehouse performance evaluation is essential for companies. But how do you measure performance, and what are the key metrics? Many business owners are not aware of these.

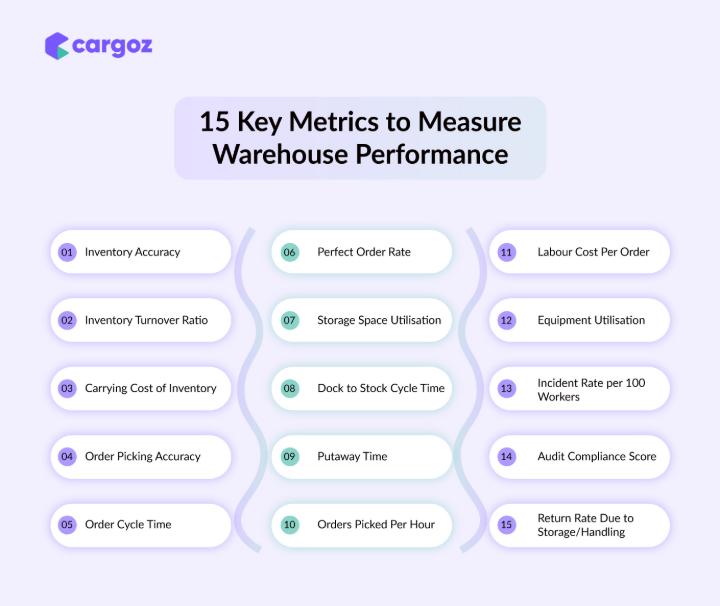

- In this blog, we will take a deep dive into key metrics that measure how effectively the warehouse is operating across important areas, including inventory accuracy, labour productivity, equipment utilisation, and order fulfilment.

Table of Contents |

● What Are the Key Metrics for Warehouse Performance Evaluation? ● What Are the Benefits of Effective Warehouse Performance Evaluation? ● Wrapping Up ● Frequently Asked Questions |

What Are the Key Metrics for Warehouse Performance Evaluation?

- Whether you are using a general goods warehouse or an AC warehouse, measuring the performance can help you improve efficiency. Here are the key metrics to consider.

-

Inventory KPIs

1. Inventory Accuracy

Inventory accuracy provides information on how closely the recorded inventory in your Warehouse Management Software (WMS) matches the actual physical inventory available in the warehouse. It reflects the reliability of your stock data and directly influences order fulfilment, replenishment planning, and customer satisfaction. High inventory accuracy reduces the risk of stockouts, overstocking, and costly errors.

Formula: (Accurate Inventory Count / Total Inventory Count) × 100

How to Improve It:

● Conduct regular cycle counts and remove discrepancies.

● Use barcode or RFID scanning to reduce human error.

● Integrate your Warehouse Management Software with real-time inventory tracking tools.

● Set automated alerts for low stock, misplaced items, or unusual discrepancies.

2. Inventory Turnover Ratio

The inventory turnover ratio measures the frequency with which a company sells and replaces its inventory within a specified period. This KPI reflects the efficiency of inventory management and is a critical warehouse quality metric for understanding the balance between sales and stock levels.

Formula: Cost of Goods Sold (COGS) / Average Inventory Value

How to Improve It:

● Forecast demand accurately using past sales data.

● Optimise reorder points and quantities.

● Remove obsolete or slow-moving stock.

● Implement promotions to clear excess inventory.

3. Carrying Cost of Inventory

Carrying cost of inventory, also known as holding cost, refers to the total cost incurred for storing unsold inventory. This includes warehousing, insurance, depreciation, obsolescence, and opportunity costs. Monitoring this KPI helps identify hidden costs and inform decisions regarding inventory levels, pricing, and procurement.

Formula: (Total Inventory Holding Costs / Total Inventory Value) × 100

How to Improve It:

● Reduce unnecessary stock through lean inventory practices.

● Consolidate Stock Keeping Units (SKUs) to minimise warehousing needs.

● Choose energy-efficient and space-optimised storage systems.

● Periodically review supplier contracts to reduce holding time.

Suggested Read: How Small Businesses Can Ensure Efficient Inventory Management

Order & Fulfillment KPIs

4. Order Picking Accuracy

Order picking accuracy is another warehouse performance evaluation metric that measures how accurately orders are picked and packed before being shipped to customers. It has a direct impact on customer satisfaction and return rates. High accuracy ensures that customers receive the correct products, reducing returns and reverse logistics costs, and improving brand trust.

Formula: (Number of Accurate Picks / Total Number of Picks) × 100

How to Improve It:

● Implement a pick-to-light or voice-picking system.

● Conduct regular quality control checks at packing stations.

● Simplify and standardise the picking process.

● Cross-train staff to handle peak periods efficiently.

5. Order Cycle Time

Order cycle time refers to the average time elapsed from the moment an order is received to the time it is shipped. It is a measure of order processing efficiency, reflecting the speed at which your warehouse can respond to customer demand.

Formula: (Shipping Time - Order Received Time) / Total Number of Orders

How to Improve It:

● Automate order processing and fulfilment workflows.

● Use real-time order tracking and dashboard monitoring.

● Streamline internal handoffs between departments.

● Keep popular items in easily accessible pick zones.

6. Perfect Order Rate

This metric tracks the percentage of orders delivered on time, complete, undamaged, and with accurate documentation. It combines several fulfilment KPIs into one comprehensive measure of the warehouse's performance in terms of order execution quality.

Formula: (Number of Perfect Orders / Total Orders) × 100

How to Improve It:

● Ensure shipping accuracy for every order.

● Conduct post-delivery audits and root cause analysis on defects.

● Improve labelling, packaging, and documentation workflows.

● Align warehouse operations closely with customer SLAs.

Space & Storage KPIs

7. Storage Space Utilisation

Storage space utilisation measures how effectively the available warehouse space is used. It compares the amount of occupied storage against the total usable storage capacity and helps optimise layout, racking systems, and overall storage design.

Formula: (Used Storage Space / Total Available Storage Space) × 100

How to Improve It:

● Adopt vertical storage systems, pallet racking and narrow-aisle racking.

● Conduct slotting analysis to reorganise high-turn items.

● Designate staging areas for inbound and outbound items.

8. Dock to Stock Cycle Time

This KPI measures the time it takes for received goods to be moved from the receiving dock to the inventory storage location. It reflects the speed and efficiency of inbound logistics processes. A shorter dock-to-stock time indicates faster inventory availability and reduced lead times.

Formula: Total Time Taken from Dock to Stock / Number of Shipments

How to Improve It:

● Pre-assign bin locations for incoming shipments.

● Use barcode scanning at the receiving and stocking stages.

● Automate putaway workflows through WMS integration.

● Reduce bottlenecks by allocating sufficient staff during peak hours.

9. Putaway Time

Put-away time is a critical warehouse performance metric that measures how long it takes to move an item from the receiving area to its designated storage location. The shorter the put-away time is, the more efficient the warehouse operations.

If put-away times are consistently high, it indicates issues such as poor warehouse layout, inefficient routing, or a lack of real-time slotting strategies.

Formula: Total Time from Receiving to Storage / Number of Items

How to Improve It:

● Optimise warehouse layout.

● Implement directed putaway systems.

● Use barcode or RFID scanning.

● Automate with conveyors or AMRs (Autonomous Mobile Robots).

Labour & Equipment Productivity KPIs

10. Orders Picked Per Hour

This KPI helps businesses track the average number of orders picked by a worker or a team within one hour. It reflects labour efficiency and helps optimise workforce allocation and scheduling.

Formula: Total Orders Picked / Total Labour Hours

How to Improve It:

● Implement ergonomic picking stations.

● Group similar orders together (batch picking).

● Use automated conveyor systems or AGVs.

● Reduce walking distances using smart layout design.

11. Labour Cost Per Order

Labour cost per order measures the total cost incurred on labour to process one order. It includes wages, benefits, and overtime associated with all tasks, including picking, packing, and shipping.

Formula: Total Labour Cost / Total Orders Fulfilled

How to Improve It:

● Automate repetitive tasks where possible.

● Utilise performance incentives to enhance worker productivity.

● Streamline processes to reduce idle time.

● Optimise shift schedules to match demand.

12. Equipment Utilisation

The Equipment Utilisation Rate is a measure of how effectively your warehouse equipment, such as forklifts, pallet jacks, conveyors, or automated systems, is utilised over a specific period. It shows the percentage of time your equipment is actively performing productive tasks versus the total available operating time.

Formula: (Actual Equipment Run Time / Total Available Time) × 100

How to improve it:

● Implement preventive maintenance schedules to reduce downtime.

● Train operators for multi-use equipment efficiency.

● Use telemetry or IoT sensors for real-time performance monitoring.

● Use smart warehousing tools like AGVs and AI to optimise and monitor equipment usage.

Safety & Compliance KPIs

13. Incident Rate per 100 Workers

This safety KPI measures the frequency of workplace injuries or accidents. It helps assess how well the warehouse enforces safety protocols and promotes a culture of safety.

Formula: (Number of Recordable Incidents × 200,000) / Total Labour Hours Worked

Please note: The number 200,000 is taken as a standard that 100 employees work 40 hours a day for 50 weeks, assuming each employee works for 40 hours for 50 weeks in a year. (40*50*100=200,000).

How to Improve It:

● Enforce safety training and PPE usage.

● Conduct regular safety drills and hazard assessments.

● Install safety signage and surveillance in high-risk zones.

● Encourage a safety-first reporting culture.

14. Audit Compliance Score

This warehouse performance KPI measures how well the warehouse complies with regulatory audits, internal SOPs, and third-party standards. It ensures traceability, accountability, and readiness for inspections.

Formula: (Achieved Audit Points / Total Possible Points) × 100

How to Improve It:

● Maintain digital logs for all processes and inventory.

● Standardise procedures using SOP documents.

● Conduct internal mock audits periodically.

● Assign a compliance officer or audit liaison.

15. Return Rate Due to Storage/Handling

This KPI tracks the percentage of returns resulting from damage or errors in the warehouse, caused by poor handling, improper storage, or environmental control failures.

Formula: (Returns Due to Handling / Total Orders Shipped) × 100

How to Improve It:

● Use protective packaging and buffer zones.

● Train staff on handling fragile or perishable items.

● Isolate high-risk goods from the general inventory.

● Perform root cause analysis on each return.

What Are the Benefits of Effective Warehouse Performance Evaluation?

Monitoring warehouse performance helps you understand how well it functions to stay competitive, reduce waste, and improve service delivery. Here are the key benefits:

1. Reduced operating costs

By tracking key KPIs, such as equipment utilisation, labour efficiency, and inventory accuracy, you can identify cost leakages and inefficiencies early. It helps you in allocating resources properly and reduces overhead in the long run.

2. Better inventory control

Metrics such as inventory turnover, accuracy, and stock-out rates help you control stock levels. This minimises overstocking, reduces holding costs, and ensures products are available when needed.

3. Faster fulfilment and delivery

Monitoring cycle time, dock-to-stock, and order picking accuracy impacts how quickly and accurately your warehouse fulfils customer orders, which is essential for meeting SLAs and improving customer satisfaction.

4. Improved labour productivity

Labour KPIs give you a picture of whether your team is operating at optimal efficiency. By tracking pick rates, putaway times, and idle times, you can allocate tasks properly and assess their performance.

5. Adhere to compliance and safety standards

By measuring Safety KPI, you can ensure your warehouse remains compliant with industry regulations in protecting workers' safety. A safer storage facility reduces downtime, boosts employee confidence, and lowers liability.

Wrapping Up

Operational inefficiencies significantly impact businesses, resulting in missed orders, slow putaways, and underutilised space and resources. However, with a consistent warehouse performance evaluation strategy, you can turn your warehouse into a strategic advantage.

If you are renting a warehouse in the UAE and want real-time visibility, reliable infrastructure, and performance-optimised layouts, a warehouse marketplace like Cargoz can help. With Cargoz, you can find fully-equipped, compliance-ready warehouses across the UAE.

Contact us to discuss your requirements, and we can help you find a storage facility that delivers excellent performance in key metrics.

Frequently Asked Questions

1. What are the early signs that my warehouse is underperforming?

If you notice slow order fulfilment, frequent stock discrepancies, rising labour costs, and equipment downtime, it means your warehouse is not performing at an optimised level.

2. How often should I evaluate warehouse KPIs?

You can track key KPIs on a weekly or monthly basis, and conduct a comprehensive performance review at least once a quarter.

3. Which software tools can help track warehouse KPIs?

Modern Warehouse Management Software (WMS) includes dashboards for monitoring KPIs like pick accuracy, space utilisation, and order fulfilment. Cargoz can help you find a warehouse with modern WMS systems.

4. Are Cargoz warehouses compliant with safety and industry regulations?

Yes, all listed warehouses on Cargoz meet the UAE's regulatory standards, and many track safety KPIs to maintain high levels of compliance.

5. Can I tour a warehouse to assess its performance setup before renting through Cargoz?

Yes, Cargoz encourages businesses to visit the site to evaluate layout, equipment, infrastructure, and ask about key performance indicators before finalising the rental.