Why does Dangerous Goods Warehousing demand specialized care? According to the UAE’s Dubai Civil Defence, improper storage of hazardous materials contributes to nearly 30% of industrial fires annually.

Improper storage can lead to severe consequences, ranging from fires and chemical contamination to heavy fines and legal action.

Storing dangerous goods alongside regular inventory without proper safeguards can pose a significant risk to employees, facilities, and the environment. Ensuring the right conditions and compliance is essential for safety and operational continuity.

Here’s what you need to know to meet regulatory demands and implement best practices for dangerous goods storage in your warehouse.

Table of Contents |

● Quick Reference Checklist ● What Are the General Principles of Dangerous Goods Storage? ● What Are the Legal and Regulatory Requirements to Store Dangerous Goods in the UAE? ● What Are the Best Practices for Handling Dangerous Goods Inside the Warehouse? ● Why Businesses in the UAE Trust Cargoz for Hazardous Goods Storage? ● Bottom Line ● Frequently Asked Questions |

What Are the General Principles of Dangerous Goods Storage?

Adequate storage of dangerous goods depends on strict adherence to safety protocols. These principles are not just guidelines—they’re non-negotiables for minimizing risk to people, property, and the environment.

1. Segregation of Incompatible Substances

Certain chemicals can react dangerously when they come into contact, even through vapours or shared spills.

Warehouses must:

● Use separate zones or containment areas for incompatible goods (e.g., acids away from alkalis)

● Follow clear labeling and classification based on hazard type

● Refer to compatibility charts to avoid storage challenges

Segregation reduces the risk of fire, toxic exposure, and uncontrolled reactions.

2. Ventilation and Fireproofing

Ventilation is essential, especially in enclosed areas where flammable vapors or gases can accumulate. It prevents the accumulation of dangerous concentrations and supports air quality for workers.

Key measures include:

● Mechanical ventilation systems for enclosed or high-risk storage zones

● Placement of exhaust points at vapor-accumulation levels (e.g., floor level for heavy gases)

● Installation of fire-resistant materials for walling, shelving, and partitions

● Fire-rated doors and thermal barriers where needed

● Combined, ventilation and fireproofing form the backbone of safe storage for dangerous goods

3. Spill Containment Protocols

Even small leaks can become significant hazards if not handled correctly. Every dangerous goods warehouse must have systems in place to contain and manage spills before they spread and cause harm.

It involves:

● Bunded storage areas with raised edges to contain spills.

● Drip trays under shelving or drums.

● Spill kits are strategically placed across the warehouse.

● Routine checks on containers and drums for corrosion or damage.

● Containment isn’t just about cleaning up—it’s about preventing exposure and escalation.

Quick Reference Checklist

A reliable, dangerous goods warehousing storage facility should always have the following:

☑ Marked zones for each hazard class

☑ Proper ventilation and air quality control

☑ Non-combustible shelving and fire-resistant barriers

☑ Emergency spill kits and bundling in place

☑ Updated segregation guidelines posted onsite

Maintaining these standards enables businesses to meet regulatory requirements while protecting both workers and assets.

What Are the Legal and Regulatory Requirements to Store Dangerous Goods in the UAE?

Dangerous Goods Warehousing in the UAE is governed by a clear set of rules that ensure safety, compliance, and environmental responsibility. Businesses operating such facilities must meet the licensing and documentation standards set by regulatory bodies, including the Dubai Civil Defence (DCD), Dubai Municipality, and relevant free zone authorities.

1.Licensing, Documentation, and Permits

Before any operations begin, businesses must secure the correct trade license that permits the storage of hazardous materials. It typically involves:

● Approval from Dubai Civil Defence (DCD) for warehouse layout and fire safety plans.

● Environmental clearance from Dubai Municipality or EHS-Trakhees, depending on the location.

● Validated storage permits based on the class of dangerous goods being handled.

● Periodic renewal of all approvals, with inspections to ensure continued compliance

● Containment isn’t just about cleaning up—it’s about preventing exposure and escalation.

Failure to secure or maintain proper licensing can result in heavy penalties, suspension of operations, or permanent closure.

2.Importance of MSDS (Material Safety Data Sheets)

Every product classified under dangerous goods must be supported by an up-to-date Material Safety Data Sheet (MSDS). These documents are essential for:

● Identifying chemical properties and hazards

●Outlining safe handling, storage, and disposal procedures

● Providing first aid measures in case of exposure

● Assisting Civil Defence and emergency response teams during inspections or incidents

All MSDS records should be easily accessible onsite, preferably in both physical and digital formats, and updated regularly by UAE regulations.

3.Mandatory Safety Equipment and Staff Training

Operators of a dangerous goods warehousing facility are responsible for equipping the facility with certified safety systems and procedures that comply with relevant regulations. These typically include:

● Fire detection and suppression systems (foam sprinklers, extinguishers, smoke detectors)

● Spill containment kits and absorbent materials for chemical leaks

● Ventilation systems suitable for the type of materials stored

● Explosion-proof lighting and electrical fittings, where applicable

● Marked emergency exits and signage in line with Civil Defence codes

In addition, every staff member handling hazardous goods must undergo:

● Formal training in hazardous material handling, aligned with local and international standards

● Emergency preparedness drills and response protocols

● Use of PPE (Personal Protective Equipment) based on material classification

4.UAE Civil Defence Alignment – Key Guidelines

Warehousing operations dealing with dangerous goods must also comply with local Civil Defence directives:

● Maintain fire-rated partitioning between incompatible materials

● Provide dedicated loading/unloading zones with containment features

● Install 24/7 surveillance and monitoring systems

● Keep updated logbooks of goods movement and storage history

● Ensure routine third-party inspections and certification renewals

Meeting these requirements is not optional—it’s fundamental for lawful, safe, and sustainable warehouse operations in the UAE.

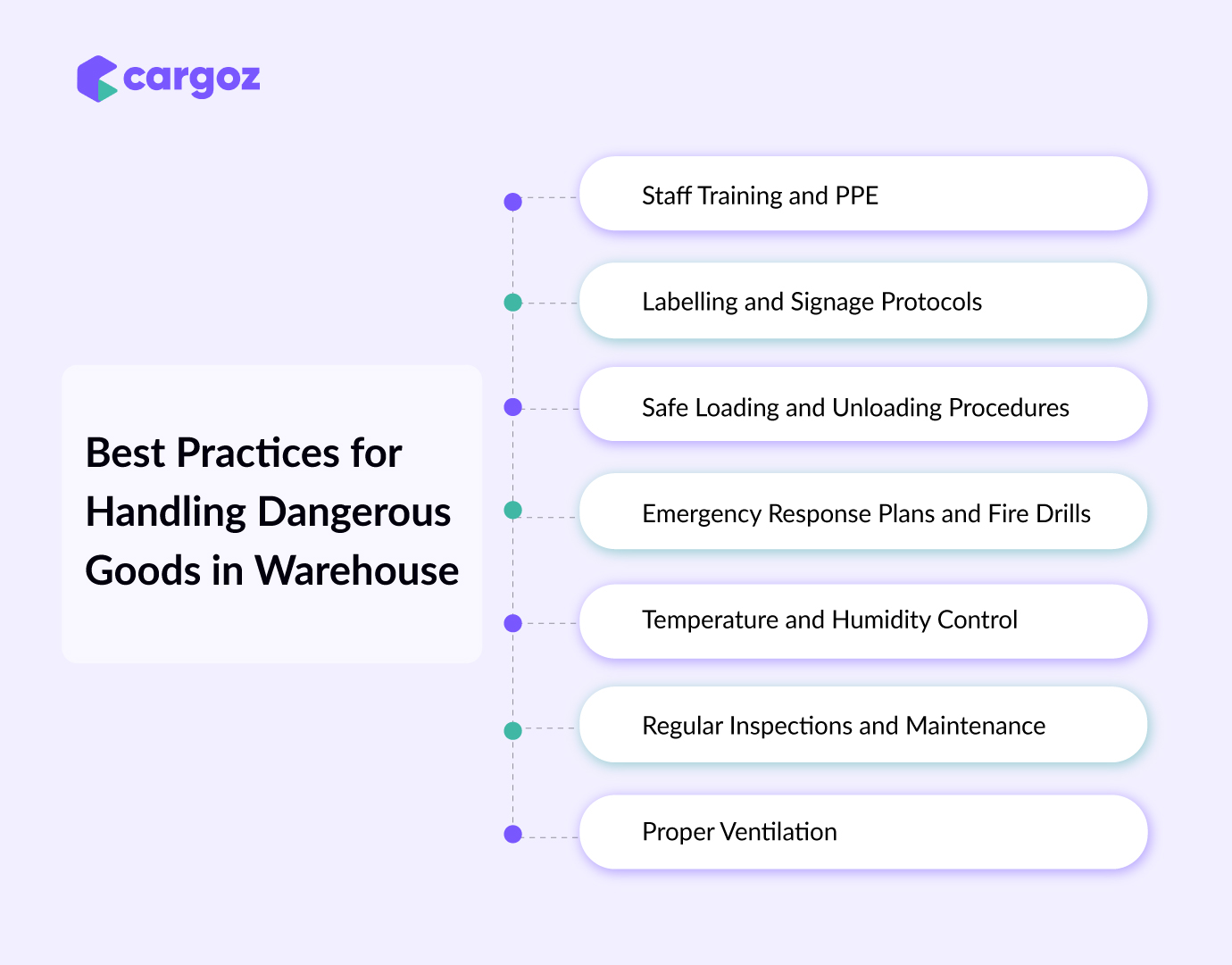

What Are the Best Practices for Handling Dangerous Goods Inside the Warehouse?

Handling hazardous materials requires more than secure storage. It demands a disciplined approach to everyday operations—from how staff are trained to how goods are moved across the facility. These practices are central to compliant and safe Dangerous Goods Warehousing.

1. Staff Training and PPE (Personal Protective Equipment)

The first line of defense in any warehouse is the people working inside it. Train employees handling hazardous materials to understand the risks involved and know precisely how to respond during both routine operations and emergencies.

Key training areas include:

● Correct handling procedures for each class of dangerous goods warehousing.

● Use and maintenance of PPE such as gloves, safety goggles, respirators, and protective suits.

● Emergency protocols for leaks, exposure, or equipment failure.

● Regular refreshers and drills are conducted to ensure high preparedness levels remain.

● Without proper training, even the best systems fall short.

2. Labelling and Signage Protocols

Clear and consistent labeling is both a regulatory requirement and a practical necessity. Every container, pallet, and storage zone must indicate the nature of the material it holds.

Warehouses should follow these protocols:

● Use internationally recognized hazard symbols and color codes

● Include handling instructions and emergency contact details where required

● Ensure all signage is weather-resistant and visible from a distance

● Regularly audit labels to confirm they are accurate and legible

● Good signage prevents guesswork and protects everyone in the facility.

3. Safe Loading and Unloading Procedures

The movement of hazardous goods—whether from trucks to racks or vice versa—is one of the highest-risk activities in a warehouse. Small mistakes can lead to spills, equipment damage, or personal injury.

To reduce risk:

● Use equipment designed for specific material weights and dimensions

● Ensure forklifts and pallet jacks are maintained and approved for use in hazardous goods warehouse areas

● Load and unload only in designated, ventilated zones

● Never stack goods beyond permitted height or weight limits

Following these steps helps maintain the integrity of goods and the safety of staff.

4. Emergency Response Plans and Fire Drills

Every facility involved in the storage and handling of dangerous goods must be ready for unexpected situations. The fires, spills, and chemical exposure incidents must be addressed within seconds, not minutes.

Best practices include:

● A documented emergency response plan aligned with Civil Defence standards

● Marked evacuation routes and muster points

● On-site fire extinguishers, eyewash stations, and first aid kits

● Scheduled fire drills and simulated spill scenarios for all staff

Preparedness is not optional—it’s a regulatory and operational necessity.

5. Temperature and Humidity Control

Certain chemicals degrade or become unstable under specific environmental conditions.

● Utilize sensors to monitor temperature and humidity in real time.

● Store temperature-sensitive goods in climate-controlled sections.

● Avoid exposure to direct sunlight or fluctuating ambient conditions that can affect material integrity.

6. Regular Inspections and Maintenance

Routine checks are essential for both compliance and safety assurance.

● Inspect storage racks, containment systems, and safety equipment regularly to ensure they are in good working condition.

● Replace damaged drums, leaking containers, or corroded shelving as soon as possible.

● Document all inspections and corrective actions for auditing purposes.

7. Proper Ventilation

Ventilation reduces the build-up of harmful vapors, especially in enclosed or high-risk zones.

● Install exhaust fans and air circulation units based on the hazard class and warehouse layout.

● Ventilation should run continuously in storage areas for flammable, volatile, or reactive materials.

● Maintenance logs should track fan performance and airflow rates.

A reliable Dangerous Goods Warehousing operation pays close attention to these details—not just to meet regulations but to create a safe working environment where risks are less and accountability is high.

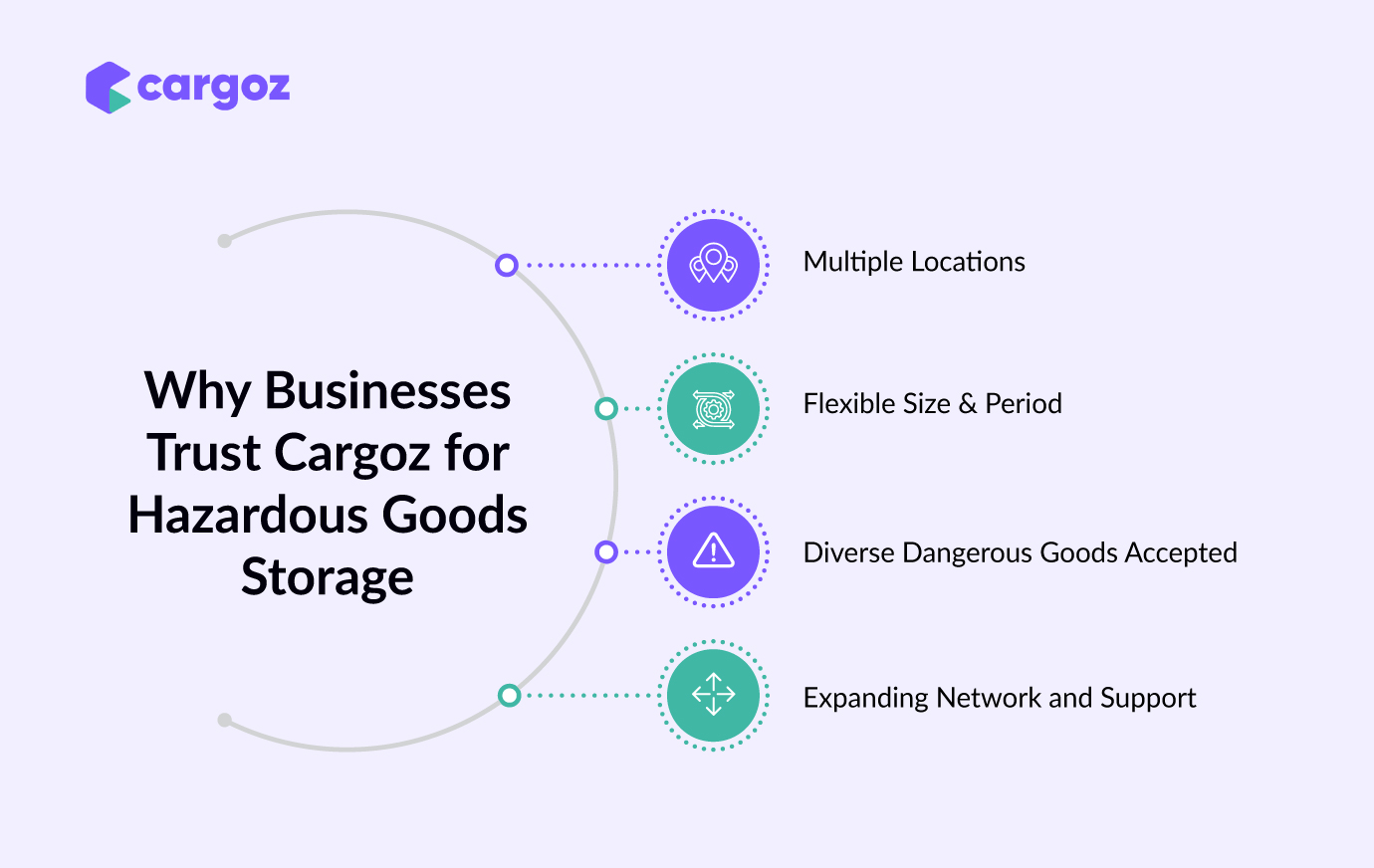

Why Businesses in the UAE Trust Cargoz for Hazardous Goods Storage?

When it comes to Dangerous Goods Warehousing, finding a reliable partner that understands local regulations and operational challenges is essential. Businesses across the UAE rely on Cargoz for flexible, secure, and compliant storage solutions specifically designed for hazardous goods.

Cargoz offers specialized, limited storage options tailored for the transportation of dangerous goods. These facilities are authorized and designed to meet strict safety and regulatory standards required for hazardous materials.

Multiple Locations

Currently, Cargoz provides dangerous goods warehouses in industrial hubs, including:

- Dubai Industrial Park (DIP)

- Dubai Industrial City (DIC)

- Jebel Ali Free Zone Authority (JAFZA)

- Sharjah Industrial Area

These locations provide accessibility, infrastructure, and compliance with regulations governing the storage of hazardous goods. You can explore the complete list of places and available options on the Cargoz platform.

Flexible Size & Period

Storage capacity accommodates up to 5 cubic meters (CBM), with no restriction on the size or quantity of goods stored within that volume. Cargoz offers flexible rental terms—weekly, monthly, or yearly—to match your business needs without long-term commitments. You can select the exact space that fits your operations through the platform.

Diverse Dangerous Goods Accepted

The warehouses currently support storage of a variety of hazardous materials, including but not limited to:

- ● Fuel and flammable liquids.

● Paints and thinners. - ● Alcohol-based perfumes

- ● Herbicides and pesticides

● Corrosive substances - ● Generators that have not purged

Expanding Network and Support

While the options for dangerous goods warehousing through Cargoz are currently limited, the network is growing steadily. New warehouse partners are regularly being added to expand the range of storage solutions available. Cargoz is ready to connect you with the most suitable options to meet your hazardous goods warehouse storage needs.

Bottom Line: Handle with Care, Store with Confidence

Storing dangerous goods carries significant responsibility. Improper storage can lead to safety hazards, financial losses, and regulatory penalties. Businesses must prioritize strict compliance with laws and regulations to protect their people, property, and the environment.

Effective Dangerous Goods Warehousing requires the right combination of certified facilities, up-to-date safety technology, and trained personnel. Selecting a trustworthy partner who understands these requirements is crucial for ensuring seamless and secure operations.

Cargoz connects businesses in Dubai, Sharjah, and across the UAE with verified, compliant warehouses equipped to handle hazardous materials safely. With flexible options and evident transparency, Cargoz makes managing your dangerous goods storage more straightforward and more trustworthy.

So, if you are looking for a secure and certified warehouse for dangerous goods in Dubai or Sharjah? Explore Cargoz’s verified listings today.

Frequently Asked Questions

Q1: What are the regulations for storing dangerous goods in the UAE?

Dangerous goods warehousing must have proper licenses, adhere to safety and fire regulations, maintain updated safety data sheets, and pass regular inspections by authorities such as the Dubai Civil Defence.

Q2: Can I store flammable goods in a regular warehouse?

No. Flammable goods require specialized, certified warehouses for dangerous goods that meet proper fire safety and ventilation standards.

Q3: How do I ensure my staff is compliant when handling hazardous items?

Provide regular training on safe handling, emergency procedures, and PPE use. Maintain records and conduct regular drills to ensure compliance.

Q4: What is the difference between hazardous and non-hazardous storage requirements?

Hazardous storage needs fireproofing, ventilation, spill containment, and segregation. Non-hazardous storage has fewer safety demands.