Quick Go-through:

Many businesses do not utilize their warehouse space as efficiently as they could because they select the wrong racking system without considering factors such as product type and operational efficiency. With so many types available, it can be confusing which one fits your needs. Read to know different racking systems, their use cases, so that you can make the right choice without guessing.

The pallet racking system can maximise your warehouse space. According to Pallet Rack Warehouse, a well-designed pallet racking system can increase storage capacity by 30–50%. However, with numerous pallet types, selecting the right one can be a daunting task. Can you choose any kind of pallet, irrespective of the goods you store?

It is not that simple because each pallet type has a specific purpose. The pallet racking system impacts warehouse operations, team safety, and the optimisation of warehouse space. So, which warehouse racking system is the best for you?

In this blog, we will discuss various pallet racking systems and their use cases, helping you select the ideal system based on your warehouse layout, SKU volume, and storage requirements.

What Are Different Types of Pallet Racking Systems?

Selecting the right pallet racking system optimises your warehouse space and protects your goods. Here are 10 essential pallet storage systems, organised by use case, to help you make the best decision for your operations:

1. Selective Racking

- Ideal for: E-commerce, 3PLs, retail with many SKUs

- Use case: If you need fast & easy access to many SKUs

- How it benefits your warehouse: Offers direct access to every pallet, making it ideal for high-turnover inventory and quick picking operations.

Suggested Read: Top 10 Tips for Efficient Stocktaking in Your Warehouse

2. Double-Deep Racking

- Ideal for: Medium-SKU volume with space-saving needs

- Use case: If you need to store more in the same footprint

- How it benefits your warehouse: Increases storage density while maintaining reasonable access, making it efficient for mid-level throughput.

3. Drive-In / Drive-Through Racking

- Ideal for: Cold storage, bulk goods, LIFO operations

- Use case: If you want to maximise storage space

- How it benefits your warehouse: Eliminates aisles by allowing forklifts to drive directly into lanes, maximising pallet positions per square meter.

4. Push-Back Racking

- Ideal for: Warehouses handling bulk but varied inventory

- Use Case: If you need high density without automation

- How it benefits your warehouse: Stores pallets on inclined carts that automatically move forward, saving space and time.

5. Mobile Racking

- Ideal for: Space-constrained warehouses

- Use Case: If you want to use every inch of floor space

- How it benefits your warehouse: Racks move on floor-mounted tracks, enabling dense storage while maintaining accessibility.

6. Pallet Flow Racking

- Ideal for: FIFO operations like food, beverage, or pharma

- Use Case: If you prioritise automation and inventory rotation

- How it benefits your warehouse: Gravity-fed lanes ensure first-in-first-out movement, enhancing inventory freshness and reducing handling.

7. Shuttle Racking

- Ideal for: High-volume, semi-automated environments

- Use Case: If you want to minimise forklift use

- How it benefits your warehouse: Powered shuttles move pallets within racks, improving safety, density, and throughput.

8. Automated Storage and Retrieval Systems (AS/RS)

- Ideal for: 24/7 fulfilment centres, pharmaceuticals, e-commerce

- Use Case: If you want complete automation

- How it benefits your warehouse: Robotic systems handle storage and retrieval, reducing labour costs and increasing order accuracy.

A Market and Market report shows that automated storage and retrieval systems (AS/RS) can help you save up to 85% of the floor space.

9. Cantilever Racking

- Ideal for: Pipes, timber, furniture, or other long/bulky items

- Use Case: If you store long or irregularly shaped goods

- How it benefits your warehouse: Open-front design supports items of varying lengths without vertical obstructions.

10. Mezzanine Racking

- Ideal for: Warehouses with high ceilings and limited floor space

- Use Case: If you want to expand storage vertically

- How it benefits your warehouse: Adds an extra floor for storage or work areas without expanding your building’s footprint.

Pro Tip: Match Rack Type to Your Workflow

- -High SKU variety + high picking speed = Selective or Flow-through

- -Low SKU variety + high density = Drive-In or Shuttle

- -Automation-ready = Shuttle or AS/RS

- -Long materials = Cantilever

- -Need to grow vertically = Mezzanine

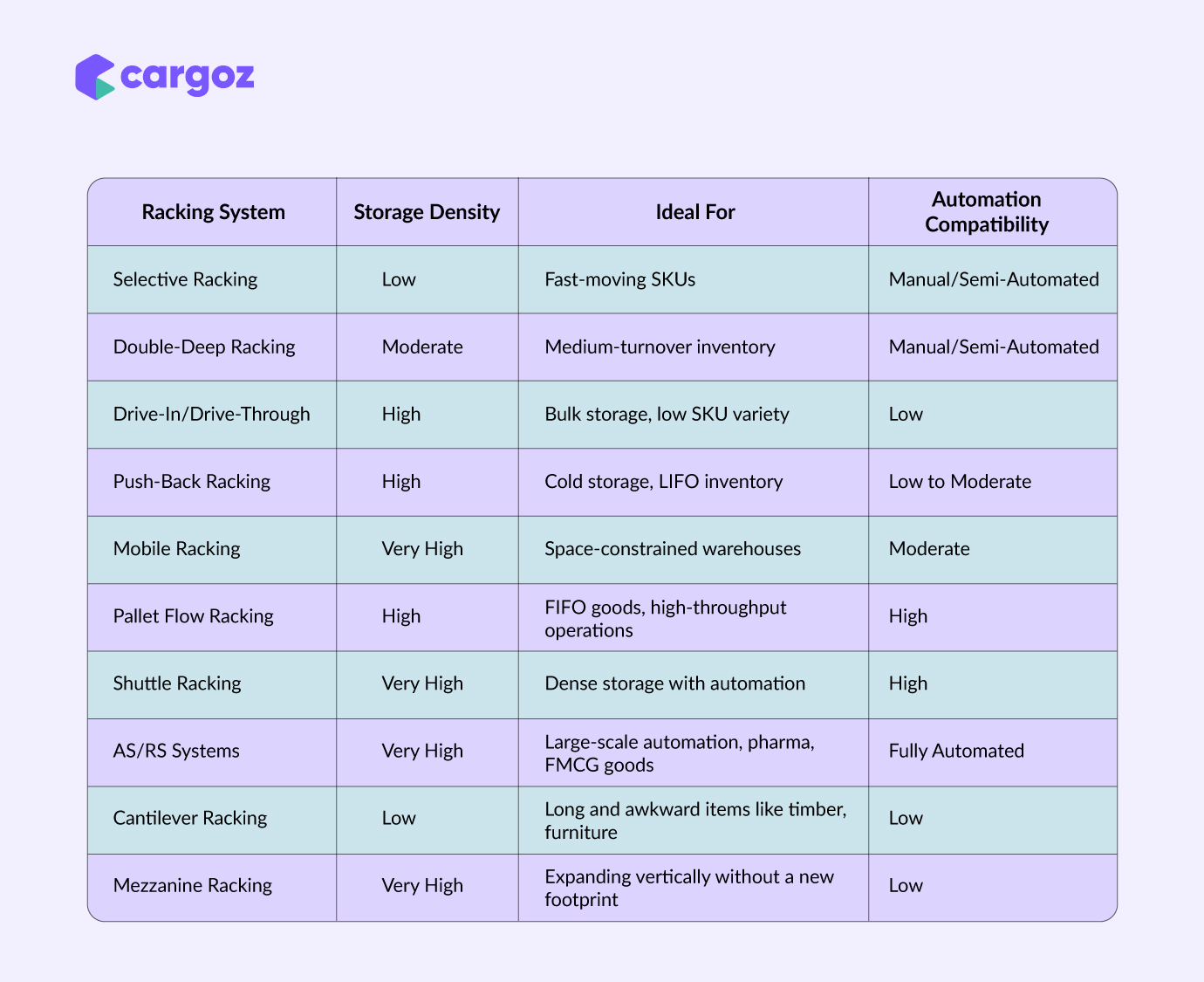

Quick Comparison of Different Kinds of Pallet Racking Systems

Also Read: Pallet Racking or Floor Stacking: Which one should you choose?

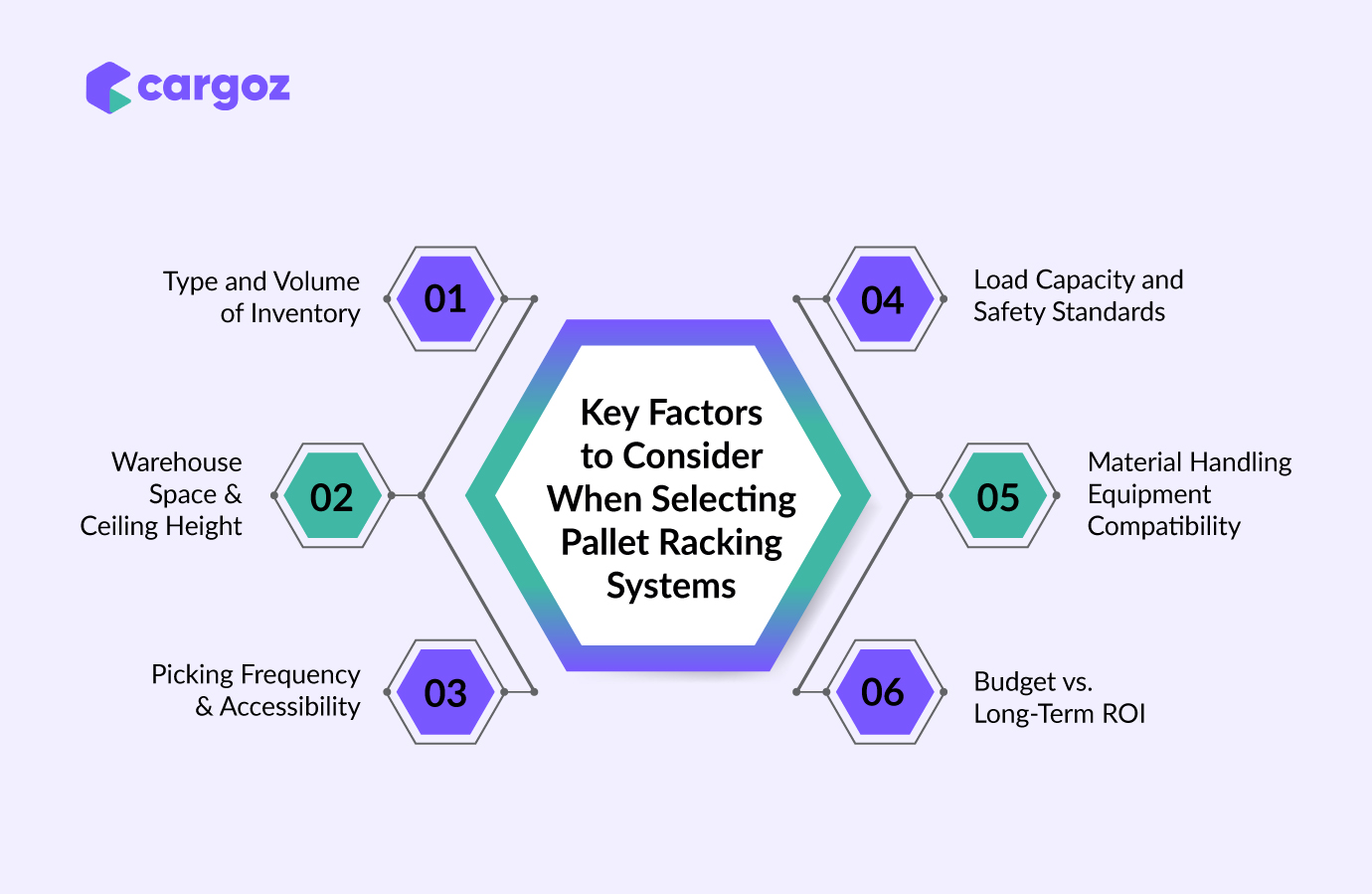

How to Choose the Right Pallet Racking System?

Proper racking prevents product damage by keeping pallets off the floor and minimising collisions during storage and retrieval. Whether you have general or sensitive goods, selecting the racking system is crucial. Here are the factors to consider before making a choice.

1. Type and Volume of Inventory

Your product size, weight, and turnover rate directly impact the racking system you need. High-volume, fast-moving inventory requires different handling than bulky, slow-moving goods.

●For high-SKU, high-turnover items, Selective or Flow Racks are ideal.

●For bulky goods with low turnover, consider Drive-In or Push-Back Racks.

● Long, irregular items, such as lumber or pipes, are best stored in Cantilever Racks.

● Consider FIFO or LIFO workflows depending on your inventory’s shelf life.

2. Warehouse Space & Ceiling Height

Maximising vertical space is as important as floor space. Ceiling height, aisle width, and floor layout all determine which warehouse pallet racking system will maximise capacity and improve efficiency.

●For high ceilings (10+ meters), consider high-bay or mezzanine racking to fully utilise vertical height without expanding your warehouse area.

● For low to mid-range ceilings (6–9 meters), use selective or push-back racking, which can work efficiently within mid-height limits and still allow accessibility for forklifts.

● For irregular layouts or tight floor plans, choose mobile racking or custom-designed systems to eliminate fixed aisles and increase pallet density in narrow spaces.

3. Picking Frequency & Accessibility

If your operations involve frequent picking or order fulfilment, easy access to each SKU is essential. This is because when your team spends too much time retrieving SKUs, it slows order fulfillment and increases labor costs.

These systems can help optimise that process:

●Selective Racking ensures direct access to every pallet, ideal for fast-moving items.

● For automation or semi-automation, shuttle racks and AS/RS systems reduce labour and speed up picking.

4. Load Capacity and Safety Standards

Before selecting a pallet racking for warehouses, you should evaluate how much weight it must handle daily. Racking failures damage your goods and put your workforce at risk. To ensure your racking system meets both operational and legal requirements, you should consider the following:

- Assess total load per pallet: Calculate the weight of each pallet, including product, packaging, and pallet itself.

- Choose rack types based on load: Use structural steel racks or heavy-duty uprights for heavier loads or dense inventory zones.

- Verify rack certifications: Ensure systems meet relevant standards mentioned by Dubai Civil Defense and Dubai Municipality (UAE), Rack Manufacturers Institure (USA), FEM Racking and Shelving (Europe), or in your respective country.

- Schedule periodic safety audits: Regular checking can help detect and address wear and tear before it becomes a hazard.

5. Material Handling Equipment Compatibility

The efficiency of your pallet racking systems depends on the material handling equipment (MHE) used. Your forklifts, pallet jacks, or automated retrieval systems must be compatible with the racking design to avoid inefficiencies and accidents to ensure safety, optimise space, and maintain smooth operations.

When aligning your racking with your MHE, you should consider:

●Forklift turning radius and aisle width must match the racking layout, especially for selective, double-deep, or drive-in systems.

●Lift height capacity should be evaluated for high-bay racking or multi-tier mezzanines.

● Shuttle or AS/RS systems must integrate with racking dimensions, power needs, and safety rails.

● Low-clearance racking may restrict the use of certain pallet jacks or stackers.

6. Budget vs. Long-Term ROI

Cost is definitely a factor when selecting a pallet racking system, but focusing only on the price is not a wise decision. The real question is: Will your investment improve operational efficiency, support future growth, and deliver better returns over time? Here is how to evaluate cost vs. return across different racking types:

●Selective Racking is affordable to install, but consumes more floor space.

●Push-back or mobile racking systems cost more upfront, but maximise space and reduce picking time.

● Automated storage retrieval systems involve high capital investment but offer efficiency for high-throughput operations.

● Evaluate the cost per pallet stored rather than just the rack installation price.

How to Find a Warehouse with the Right Racking Type in the UAE?

Finding a warehouse that offers the racking system according to your needs can be time-consuming. But do you know that a trusted warehouse marketplace like Cargoz can help you find a storage facility with the desired pallet racking system quickly?

Moreover, Cargoz offers on-demand warehousing across the UAE so that you don't need to rent an entire facility. Instead, you can select a space as low as 50 SQ. FT and expands as your demand grows. Here are some of the warehouse types you can find at Cargoz:

● AC storage

● Dry storage

● General goods warehouse

● Open yard

● Food grade warehouse

●Cold storage

● Medical storage

● Dangerous goods warehouse

Final thought

Selecting the right pallet racking system that matches your business needs and inventory flow is essential. It directly impacts your speed, safety, and scalability. Once you know the right system for your storage needs, the next step is to find a warehouse provider that offers it.

At Cargoz, we can help you discover, compare, and rent warehouses that match your operational needs. Contact us to explore our warehouses and find the best option that suits your needs.

Frequently Asked Questions

1. What is the best pallet racking system for high-density storage?

Drive-in, push-back, and mobile racking systems are better for maximising space in high-density storage environments.

2. Can pallet racking systems be customised for irregular-shaped goods?

Yes, the cantilever racking system is suitable for long or bulky items like timber, pipes, and furniture. Custom configurations are also available for unique storage needs.

3. Does Cargoz offer warehouses that support heavy-duty racking systems?

Yes, Cargoz offers various warehouses located across the UAE, supporting structural steel racking and high-load capacity systems suitable for industrial storage.

4. Does Cargoz provide short-term warehouse rentals with racking available?

Yes, Cargoz offers short-term and seasonal warehousing solutions, equipped with different pallet types. Contact us to discuss your needs, and we will provide the best option.

5. Does Cargoz help with setting up racking inside the rented warehouse?

This depends on the warehouse provider. Some warehouses allow customisation, but that needs to be discussed before renting. You can mention your racking needs, and we will help you find the best one.