A single incident in a chemical warehouse can shut down an entire city for days. That is exactly what happened in May 2025, when fire and toxic fumes in a chemical warehouse in Seville, Spain, forced 80000 people to stay indoors.

Sounds alarming?

This is just one example of why chemical storage is challenging. If you work with industrial chemicals, it is essential to understand the challenges of storing them and how to address these challenges effectively.

That's why in this blog, we will discuss the key challenges of chemical storage, their solutions, different types of chemicals, and their specific storage need

Table of Contents

|

|

What are Chemical Storage Spaces?

Chemical warehouses are storage facilities where businesses can store their chemical products safely, eliminating the risk of potential hazards.

These storage spaces must meet stringent safety, environmental, and regulatory standards to prevent leaks, contamination, explosions, or other accidents.

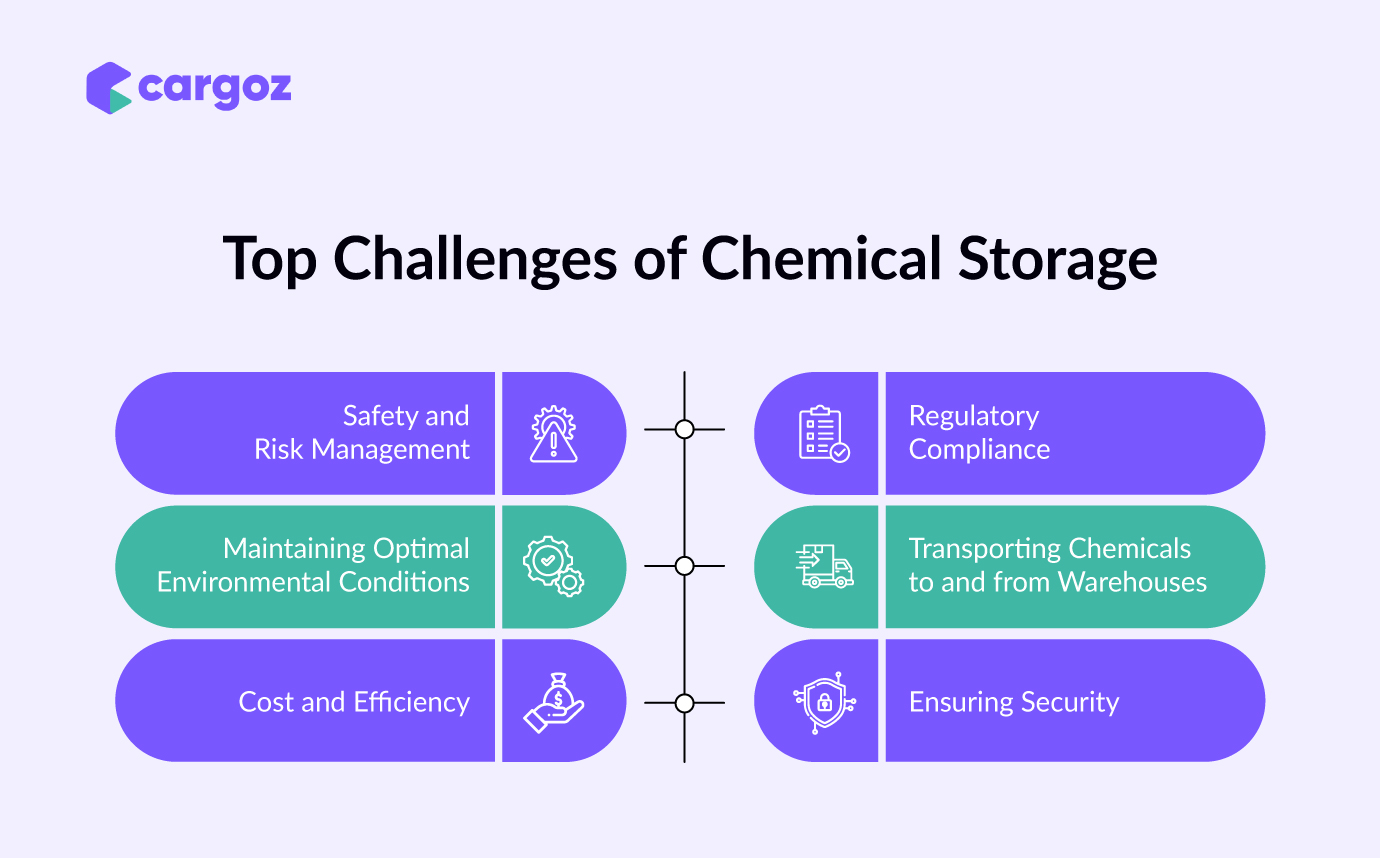

What Are the Challenges of Chemical Storage and Their Solutions?

Storing chemicals involves several challenges, like safety, strict regulations, and more. Here are the top challenges and their solutions.

1. Safety and Risk Management

Challenge:

Safety is a major concern when storing chemicals because a single mishap, such as a leak, a spark near a flammable solvent, or inadequate ventilation, can quickly escalate into a disaster. Many businesses struggle to find storage spaces that can safely handle such risks daily.

Solution:

- Rent chemical storage spaces that are designed for storing hazardous materials.

- Avoid average storage units that lack proper safety infrastructure.

- Look for warehouses with fire-rated zones, adequate ventilation, spill kits, and built-in drainage systems.

- Flameproof electrical fittings to eliminate ignition sources near flammable substances

Ensure the facility complies with local safety and environmental regulations.

For example, a warehouse storing flammable liquids should have flameproof fittings and built-in drainage to contain spills and prevent any accidents.

2. Regulatory Compliance

Challenge:

With numerous incidents of fire in chemical storage spaces occurring almost every year, governments and authorities worldwide have implemented stringent regulations for storing chemicals in warehouses. Failing to adhere to this can have serious consequences, including accidents, massive fines, and legal complications.

Solution:

- When renting a chemical warehouse in the UAE, verify that the warehouse has approvals from relevant agencies, such as the Dubai Civil Defence (DCD).

- Ensure the facility complies with international safety standards for handling hazardous materials.

- Look for credentials that confirm the warehouse follows environmental and safety regulations.

- Avoid uncertified storage spaces to prevent legal issues, penalties, or safety breaches.

3. Maintaining Optimal Environmental Conditions

Challenge:

Many chemicals are sensitive to fluctuations in temperature and humidity, posing significant risks when there is inadequate climate control. It can cause degradation and even dangerous reactions, especially with chemicals such as hydrogen peroxide or industrial adhesives.

Solution:

- Choose climate-controlled chemical storage spaces to maintain stable temperature and humidity levels.

- Ensure the facility has systems to regulate environmental conditions based on the chemical type (e.g., flammable, volatile, reactive).

- Look for warehouses with monitoring tools that alert for changes in temperature or humidity levels.

4. Transporting Chemicals to and from Warehouses

Challenge:

Moving chemicals to and from the warehouse is another challenge due to hazards, risks of spills, leaks, chemical reactions, and explosions. According to a report by the Institution of Chemical Engineers, a recent analysis of over 1,600 hazardous chemical incidents found that 65% were either entirely or partially caused by human error.

Solution:

- Ensure trained personnel handle loading and unloading.

- Label and segregate incompatible chemicals during transport.

- Use spill-proof packaging and secondary containment where necessary.

- Equip transport units with emergency response kits and personal protective equipment (PPE) to ensure the safety of personnel.

- Use certified chemical transport vehicles with proper containment systems.

5. Cost and Efficiency

Challenge:

Storing chemicals safely comes at a cost, and cutting corners is not an option. High safety standards often mean higher expenses, and maximizing the use of your space without compromising safety is not always easy.

As a business owner, it can feel like choosing between safety and budget. If you focus too much on the budget, you might have to compromise safety. But if you prioritize safety, your profit margins could take a hit.

Solution:

- Choose a chemical warehouse that optimizes space utilization without compromising on chemical compatibility or segregation.

- Ensure the warehouse has segregation zones to prevent cross-contamination and accidents.

- Look for providers that offer flexible storage plans, such as pay-per-pallet or short-term and long-term renting, to match your budget and scale.

- Select on-demand warehousing that allows you to rent only the space you need rather than renting an entire warehouse.

If you are not sure about selecting chemical storage spaces, check out our guide on How to Choose the Best Chemical Warehouse for expert advice.

6. Ensuring Security

Challenge:

Security is a major concern for warehouses, and chemical storage facilities are no exception. Unauthorized access in a chemical storage warehouse can be a serious threat not only because of theft, but also tampering with chemicals can cause an explosion and put warehouse staff and serious risk to warehouse staff. It can also have environmental consequences for businesses.

Solution:

- Look for chemical storage warehouses with security systems like 24/7 CCTV surveillance to monitor activity and deter unauthorized access.

- Ensure the facility has restricted access zones where only trained personnel can enter.

- Choose warehouses with security personnel trained in hazardous material protocols.

- Check for facilities with digital access logs to track who enters and exits sensitive areas.

Confirm the presence of intrusion detection systems and alarms for potential breaches or emergencies.

Suggested Read: 7 Actionable Measures for Ensuring Warehouse Security

What Are the Different Types of Chemicals and Their Storage Needs?

Chemical Type | Examples | Storage Needs |

Flammable | Ethanol, acetone, gasoline, kerosene | |

Corrosive | Sulfuric acid, hydrochloric acid, sodium hydroxide |

|

Toxic & hazardous | Cyanide compounds, pesticides, and formaldehyde |

|

Oxidizing Agents | Hydrogen peroxide, ammonium nitrate, potassium permanganate |

|

Reactive Chemicals | Sodium metal, lithium, phosphorus, and peroxides |

|

Compressed Gases | Oxygen, nitrogen, acetylene, LPG |

|

Cryogenic Chemicals | Liquid nitrogen, liquid helium |

|

Perishable or Temperature-Sensitive Chemicals | Certain pharmaceuticals, biotech reagents, and enzyme solutions |

|

Conclusion

Chemical storage is challenging, and there is no scope for mistakes when selecting the right space. You can avoid costly mistakes and protect goods, people, and the environment when you understand the risks and take the proper precautions.

At Cargoz, we offer secure and compliant chemical warehouses for rent in Dubai and across the UAE to help businesses store their goods. Whether you need a warehouse for short-term or long-term storage, Cargoz can provide the right storage solution. Contact us to discuss your requirements.