Can you select any pallet for your warehousing operations?

Pallets are simple platforms, but they can have a significant impact on your warehousing operations. Selecting the wrong pallet can slow down workflows and increase the risk of product damage.

From global logistics operations to last-mile delivery, the right pallet reduces logistics costs and ensures compliance with the warehousing and logistics standards. That is why understanding the pallet type and identifying the best fit for your business is essential.

But with so many pallet types available, how do you choose the right one? In this blog, we will explore different types of pallets in warehouse and the key factors to consider when selecting them.

Table of Contents |

●Why Do You Need Pallets in Warehousing? ●What Are the Different Types of Pallets in Warehouse? ●What are the Key Factors to Consider When Selecting Pallets? ● Final Takeaway ●Frequently Asked Questions |

Why Do You Need Pallets in Warehousing?

1. Pallets utilize space more efficiently and help organize the warehouse better.

2. Faster unloading and loading of delivery vehicles.

3. Safety of workers. Using forklifts to lift the goods is much safer than having people deal with it. The labour cost would also see a dip.

4. Increased warehouse efficiency due to better organization.

5. The risk of damage is less as goods are correctly stacked in storage and transport.

6. Warehouse space is optimized. Pallet racking is built vertically, saving much warehouse space.

What Are the Different Types of Pallets in Warehouse?

Choosing the right type of pallet is crucial because it can significantly impact your warehousing efficiency, operational costs, and product safety. Let’s look at different types of pallets based on their dimensions, materials, entry points, and special features.

1. Pallets by Dimensions

Euro Pallet

●Size: 1200mm x 800mm

●Region: Commonly used across Europe and the Middle East

●Load Capacity: 1 to 1.5 tons

Note: Regulated by the European Pallet Association (EPAL)

American Pallet (Universal Pallet)

●Size: 1200mm x 1000mm

●Region: Widely used in the USA and Japan

●Load Capacity: Up to 1500 kg

Note: Known for compatibility with international freight systems

2. Pallets by Material

Wooden Pallet

●Material: Oak, elm, or maple wood

●Use Case: Ideal for general-purpose and heavy-load warehousing

Pros:

- Easy to repair and recycle

- Eco-friendly with a long lifecycle

- Excellent load-bearing strength

- Easy to repair and recycle

- Cons:

- Hard to clean and sanitize

- Can harbor moisture or pests

- Hard to clean and sanitize

Plastic Pallet

●Material: HDPE or PET

●Use Case: Pharmaceutical, chemical, and food-grade supply chains

Pros:

Lightweight and resistant to contamination

- 100% recyclable and durable

- Easy to clean and store

- 100% recyclable and durable

- Cons:

- More expensive than wooden pallets

- Not repairable when damaged

- More expensive than wooden pallets

Metal Pallet

●Material: Steel or aluminum

●Use Case: Heavy industrial applications, exports under strict hygiene standards

- Pros:

- High durability and heavy load capacity

- Resistant to pests, chemicals, and corrosion

- Easy to sanitize

- High durability and heavy load capacity

- Cons:

- Higher upfront and transport costs

- Higher upfront and transport costs

Cardboard Pallet

●Material: Corrugated fiberboard

●Use Case: Lightweight, single-use shipping (e.g., e-commerce)

- Pros:

- Cost-effective and recyclable

- Ideal for air freight due to lightweight

- Cost-effective and recyclable

- Cons:

- Not water-resistant

- Shorter lifespan

- Not water-resistant

Which Pallet Material Is Right for Your Business? A Quick Comparison

The use of pallets in warehouse operations varies based on the material, as each type has specific advantages in terms of load capacity, durability, and cost-effectiveness. Refer to this table to determine which material best suits your needs.

Pallet Type | Material | Load Capacity | Cost | Durability | Best Use Case |

Wooden | Oak/Elm/Maple | Medium to High | Low | Medium | General-purpose |

Plastic | HDPE/PET | Medium | High | High | Food/Pharma |

Metal | Steel/Aluminum | High | High | Very High | Heavy-duty/Export |

Cardboard | Fiberboard | Low | Low | Low | Single-use/Airfreight |

3. Pallets by Entry Points

4-Way Entry Pallet

●Accessible from all four sides by forklifts and pallet jacks

●Offers maximum flexibility in warehouse layout and loading efficiency

2-Way Entry Pallet

●Accessible from only two opposite sides

●Lower maneuverability but suitable for static storage setups

4. Other Specialized Pallet Types

Stringer Pallets

●Uses parallel stringers to support unit loads

●Common in North America

●Offers basic structural strength

●Best For: General warehousing with moderate load requirements

Block Pallets

● Built using solid blocks instead of stringers

●Supports four-way entry by forklifts

●Made of wood, plastic, or plywood

●Best For: Heavy loads and automated handling systems

Double-Face Pallets

● Has decks on both top and bottom surfaces

●Available in reversible and non-reversible formats

●More durable and stable than single-face pallets

●Best For: Heavy-duty industrial applications

Double-Wing Pallets

● Deck boards extend beyond the stringers like wings

● Increases surface area and stability

●Best For: Maximizing load space in shipping containers

Solid Deck Pallets

● One continuous top sheet with no spacing

● Prevents small items from falling through

●Best For: Pharmaceutical and food-grade logistics

Roto-Molded Pallets

● Made using the rotational molding process

● Weatherproof, termite-resistant, and highly durable

●Best For: Outdoor storage and hygiene-sensitive industries

Injection-Molded Pallets

● Made from high-quality HDPE, PP, or PE

● Highly uniform and resistant to impact

●Best For: High-rack warehouses and precision logistics

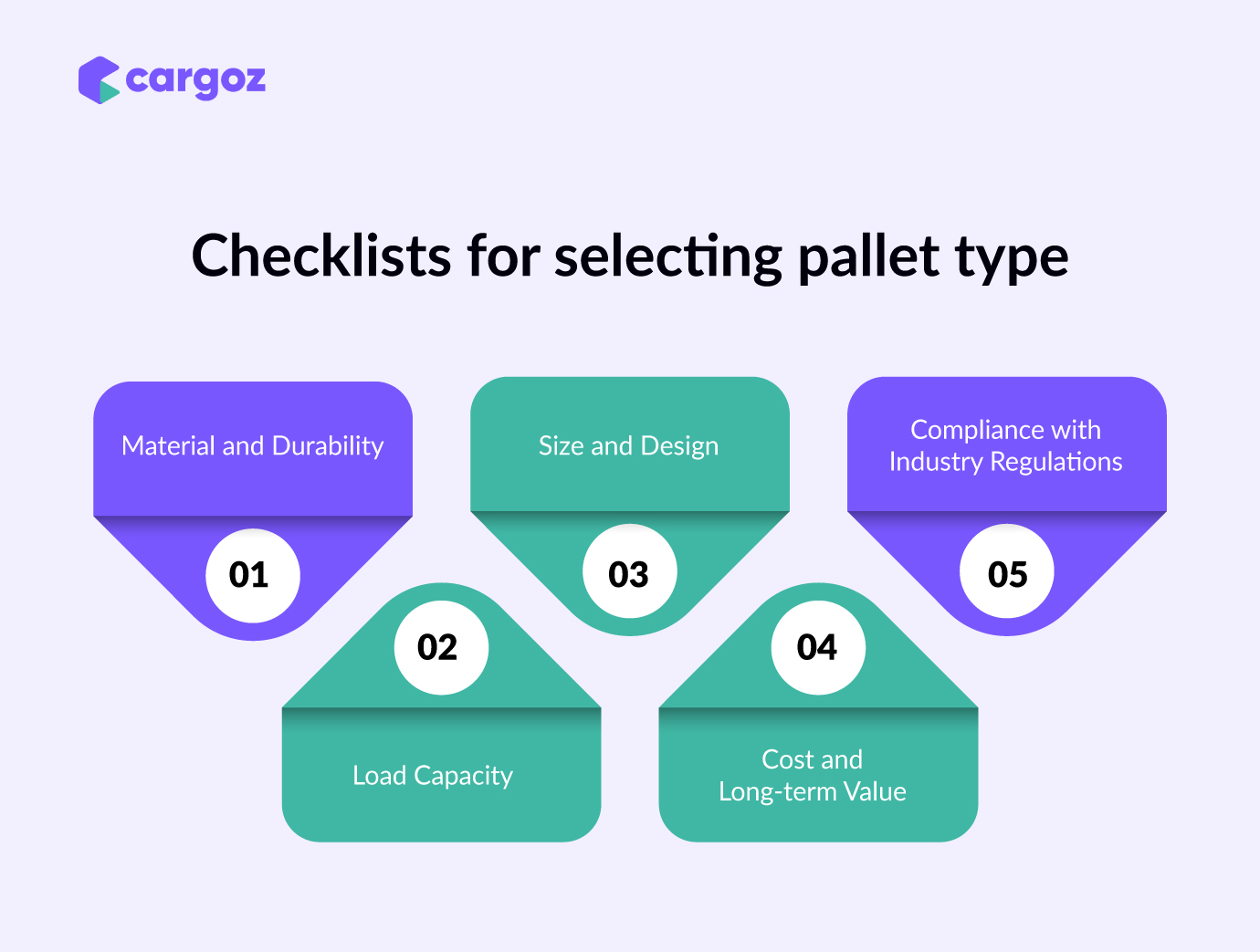

What are the Key Factors to Consider When Selecting Pallets?

Selecting the right types of pallets in warehouse is important as it impacts your warehouse operations, goods' safety, and optimizes space utilization. Here are the key factors to consider.

1. Material and Durability

- -Wood pallets are cost-effective, widely available, and ideal for general warehousing needs.

- -Plastic pallets are durable, easy to clean, and suitable for regulated industries like food or pharma.

- -Metal pallets are the most durable and are ideal for handling heavy loads or long-term storage.

Tips: When selecting pallet materials, consider lifecycle costs. Plastic and metal may cost more upfront, but last longer and are more resistant to environmental conditions.

2. Load Capacity

- -Ensure the pallet can safely hold your heaviest stock that you usually load.

- -Light-duty, medium-duty, and heavy-duty pallets are available—match them to your SKUs.

- -Use manufacturer ratings to compare dynamic (in-use) and static (stacked) load limits.

- -Match pallet size to racking systems, product dimensions, and handling equipment (like forklifts).

Apart from choosing pallets with the right load-bearing capacity, ensuring they are securely wrapped is also critical. Explore the different types of pallet wrapping techniques to protect goods from damage during movement.

3. Size and Design

- -Choose pallet sizes that fit seamlessly with forklifts, pallet jacks, and racking systems.

- -Decide between a 2-way and a 4-way entry design based on warehouse traffic flow.

- -Select pallets that work well with automated systems, such as conveyors or AS/RS systems.

4. Cost and Long-term Value

- -Don't consider only the upfront cost; instead, evaluate long-term value

- -Consider potential damage or replacement costs if you opt for cheaper pallets.

- -Plastic and metal pallets may offer better return on investment (ROI).

5. Compliance with Industry Regulations

- -Use ISPM-15 certified heat-treated wood to comply with international shipping standards.

- -Plastic pallets are preferred in food, pharmaceutical, and cleanroom settings.

- -Some pallets come with certifications like GMP, HACCP, or FDA compliance.

Final Takeaway

In this guide, we have covered the key pallet types—wooden, plastic, metal, and cardboard, and other types. Different types of pallets in a warehouse are designed for specific handling and storage needs. Choosing the right one depends on factors like load requirements, compatibility, cost, and compliance. Making the right call boosts efficiency and ensures safer, smoother logistics.

If you are not sure which pallet fits your warehousing needs or need flexible storage options, Cargoz can help. As a warehouse marketplace, Cargoz helps businesses find trusted and flexible storage solutions tailored to their needs. Contact us for your warehousing needs.

Frequently Asked Questions

- What is the most commonly used pallet size worldwide?

The 1200mm x 1000mm pallet, also known as the universal or ISO standard pallet, is commonly used in international logistics, especially in North America and Asia.

- How do I choose the right pallet for my warehouse?

To select the most suitable pallet, consider factors such as load weight, product type, environmental conditions, and industry-specific compliance standards.

- Does using the wrong pallet increase shipping costs?

Yes, heavier or non-optimized pallets add more weight and volume to shipments, increasing shipping charges, especially for air and sea cargo.

- Can Cargoz connect me with pallet-racking equipped warehouses?

Absolutely, we offer pallet warehouses across the UAE with racking systems to support efficient vertical storage and better inventory access.

- How can I find a warehouse that suits my needs through Cargoz?

At Cargoz, you can check various warehouses in the UAE, based on the location, goods type, storage type, and temperature, and contact us. We can help you rent the perfect storage facility based on your business needs.